PRODUCTS

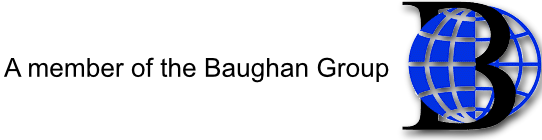

The internal surge hopper provides flexible surge capacity, allowing Shuttle Car or Scoop to discharge material at its maximum rate. The integral flight conveyor provides direct force to the material for a positive feeding action to the breaker shaft, ensuring efficient material sizing. The powerful rotary pick breaker, with breaker picks and a pick pattern designed to work with the flight conveyor, fractures material to the required output size. Since the material is fractured, rather than crushed, lumps are a consistent, easily handled size. Fewer fines are generated, maximizing the product value. As material is processed through the feeder breaker, it is discharged onto the belt conveyor at a consistent, user-controlled rate that the belt can accept. This virtually eliminates spillage, reduces wear, significantly increases belt life, and maximizes material handling system efficiency.

The Churston Underground Feeder Breaker uses specially manufactured high-strength engineered 4 inch pitch conveyor chain, with hardened link pins, for long life, low maintenance, and superior dependability. The breaker drives are electro-mechanical, direct-drive utilizing robust geared drives for maximum performance, reliability and availability.

The Churston Feeder Breakers is designed for maximum space efficiency by including an integrated surge hopper , a robust flight conveyor, and a rotary pick breaker in a single, low and high-profile machine. Crawler, wheel or skid-mounting options provide mobility to reduce Shuttle Car cycle time and increase productivity.

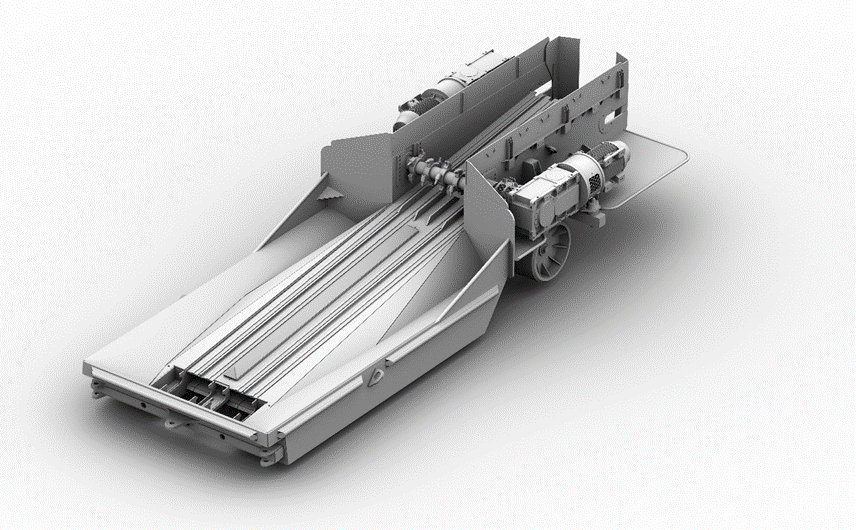

The Churston “OX Chain” is a derivative of European Standard mining chain that has been adapted to suit the Coal Mining Industry providing a cost effective solution for discharge conveyors used on all types of shuttle cars.

The Churston Ox Chains are made so that all mating parts are engineered to form a reliable long lasting assembly. Metallurgical selection is a key consideration to ensure optimal life is achieved without compromising strength and wear life. The expectation is that the chain will last for about 400,000 tons or rebuild to rebuild, subject to maintenance practices and mining conditions.

Churston manufactures most take-up and drive shafts for shuttle cars. In most cases our engineers have improved these to provide maximum life through careful selection of material and strengthening where required.

The shafts are available in various width selection to suit most applications. These include shafts for, Joy nominal 3 1/4 in pitch, Cincinnati 2 7/8 in pitch and the 18 x 64 Ox Type conveyor chain.

Churston chain is 100% locally South African. The Flightless chain is available in standard 4” for Feeder Breakers and the Flight bar chain is available in 4, 5 ½ and 6 “ for Reclaim Feeders and ROM Plant Feeders .The Flight chain is available in 4, 5 ¼ ” or 6” pitch dual flighted chain making it directly interchangeable with other non OEM flight chains for continuous miner, shuttle cars, gathering arm loaders etc.

With the exception of the connecting pin, all parts are hot upset forged. Pin and connectors have been metallurgically selected to provide maximum life as well. The Chains are available in a various widths to suit most applications.

The chains have been specifically designed to carry the load on the “center string” rather than on the flight bar ends in order to increase overall life. Length can be assembled to suit the application.

Standard flight section widths

570 mm (22.44 in.)

673 mm (26.49 in.) (Joy D Car)

750 mm (29.52 in.)

810 mm (31.88 in.)

Churston makes a variety of sprockets for mining chains from carefully selected material and heat treated to provide maximum life.

All sprockets are field proven.

The Churston Bearing Carrier has been specifically designed to give maximum trouble free life. It was developed in conjunction with major mining house engineers in South Africa.

It can be supplied as a direct fixture onto the body or mounted onto a removable plate. It is also available with a “sealed for life” bearing.

TRACK CHAINS

The ABM series chains are available to fit the entire range of Sandvik (Voest Alpine) MB300/400/600/700 (ABM12/14/20/25/30) range of Continuous miners.

The length and grouser configuration can be adopted to suit the application and the machine type.

Field tests have proven that the Churston’s forged ABM series crawler chain outlasts any cast chain available on the market today.

Churston’s 12HM range of chains are suitable to be used on the Joy HM9, HM21, HM31 as well as the “Matla Miner”.

The chain is manufactured using a forged process and grouser configuration can be adapted to customer site application.

The Churston 14BU Loader crawler chain is manufactured from a high quality casting and has the added feature that the hinge pin is not pressed in making maintenance on the chain safer and easier.